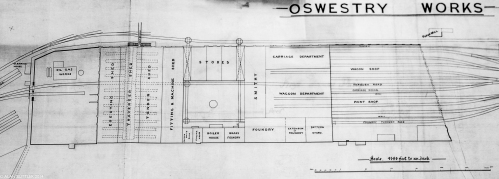

It has been some time since I looked at the plans for Oswestry Works, but with Modelu now more established I can start to put some time back into modelling. I’ve picked up where I left off after meeting up with former Oswestry men, John Morris and John Dyke, who convinced me to model the machine shop.

Oswestry Works Machine Shop

The machine shop at Oswestry is now a antiques dealership, with many original features still visible including the large doors at the entrance to the inner works yard, original beams and rafters in the roof and all of the brickwork exposed. I dropped in to get some photographs earlier in December and whilst wandering round the antique brick-a-brack found a nice 1940’s suitcase. It has made a nice addition to my body scanning wardrobe and still has an original GWR luggage label, marked Shrewsbury to Montgomery.

Researching the equipment in the machine shop has been helped by the book “Steam Workshops of the GWR“. This shows the position of machine tools and fitters benches. In the cut-away that I’ll be modelling, equipment included a boring machine, lathes and grinding machines, a wheel centre slotter and a screw cutting machine.

Many of these would have been provided by Sharp Stewart & Co who designed and fitted the works. Grace’s Guide collection of Engineer magazine articles and http://www.lathes.oc.uk provide a number of images and drawings which will help recreate these. Geoff Charles also captured some of these machines in use on his visit to the works in the 1950’s.

Operational / Demonstration Machine Shops

I made a few visits in 2014 to a number of machine shops around the country, including preserved examples at the STEAM museum and Manchester MOSI, both featuring belt driven machine tools. Trips to the former GWR machine shop at the Vale of Rheidol shed in Aberystwyth and the machine shop at Didcot also helped give an idea of how a working machine shop looks and feels.

STEAM Museum – Lang Lathe

STEAM Museum

Aberystwyth MPD – Fitters bench

Aberystwyth MPD – Machine Shop

Manchester MOSI

Didcot

Didcot

Didcot Machine Shop

Didcot Machine Shop

Didcot Machine Shop

Designing the Machine Shop

Designing the works structures uses a combination of 3D and 2D CAD. In the first stage, Sketchup is used to create a 3D mock up using photos and measurements for reference. This mock up has very limited detail, essentially just the cuts where windows, doors and any other features will be. The material thickness of the MDF to be used is extruded in 3D, allowing the model to be built virtually.

Once the outer dimensions and features of a wall are completed, the wall can be viewed in 2D mode and exported as a DXF ready for brickwork to be added in Draftsight. To make this operation easier, I use groups and components extensively in Sketchup, in order to isolate individual items. Using the Outliner gives an overview of how the components and groups are nested and provides a quick way of hiding items. Switching to parallel projection view mode, the element can be then viewed in 2D ready for exporting. DXF export will export whatever is on the screen, so all other items must be hidden prior.

Works Sidings & Templot

In addition to the machine shop, I’ve also added a number of the works sidings and the goods thru road to the outside of the works. The plan is to use this area for photographs of stock and to test out new Modelu components, including GWR concrete pot sleepers, Cambrian chairs and GWR slide chairs. I used Templot for the first time to plan the track work out and found the DXF import feature of great use. In Sketchup turning off the roof artwork group and switching to a plan 2D view allowed for a DXF export of the mock up to then be imported into Templot.

Once the trackwork was completed, this could then be exported as a solid 3D DXF and imported back into Sketchup.

Next Steps

Geoff Taylor has been giving me some great advice on how to tackle this project. Our first plan is to trial some painting techniques of the inner walls. Looking at photographs shows they are heavily coated in many layers of paint with the brickwork barely visible. I’m hoping to save time on laser cutting by using a paint/powder mix to coat the walls and give them a little texture. If that goes well, then the walls of the main works buildings will be cut. The outer yard buildings need finishing as does the works footbridge and the outer yard wall. The roof will be removable so some thought will be given to producing the beams and rafters using brass rod to keep it strong.

That’s pretty much where I’m up to after blowing the dust off the plans over Christmas. I’m hoping during 2017 to get a bit more balance and be a little stricter with myself regarding free time. Working at home has its advantages but it has been very hard to switch off and lock up the Modelu workshop!

All the best for 2017 and thanks for looking,

Alan